Stroomadapters zijn essentiële elektronische gadgets die worden gebruikt om elektriciteit om te zetten voor een breed scala aan apparaten, waaronder laptops, mobiele telefoons en huishoudelijke elektronica. Of u nu een USB-stroomadapter, laptoplader of universele reisadapter gebruikt, de betrouwbaarheid en efficiëntie van deze apparaten zijn sterk afhankelijk van hun productiekwaliteit. Hier vindt u een gedetailleerde blik op hoe stroomadapters zijn gemaakt.

1. Ontwerp en techniek

Elke stroomadapter begint met een ontwerp. Ingenieurs moeten schakelschema's maken voor de omzetting van AC naar DC, waarbij compatibiliteit met verschillende spannings- en stroomsterktevereisten wordt gegarandeerd. Deze fase omvat ook de selectie van componenten voor verschillende modellen, zoals AC-voeding, DC-voeding en AC/DC-adapters.

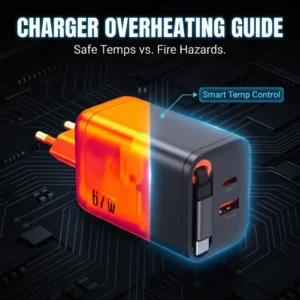

Zo vereisen USB-snellaadpoorten met 100W GaN-wandlaadtechnologie een nauwkeurig thermisch en energiebeheer om snel opladen zonder oververhitting te ondersteunen.

2. Componenten sourcing

Belangrijke componenten zijn onder meer: IC-chips, transformatoren, condensatoren, gelijkrichters, spoelen, weerstanden, enzovoort. De belangrijkste component is de IC, die op één enkele pcba voorkomt.

Adapterfabrikanten kopen deze onderdelen in op basis van prestaties, compatibiliteit, kosten, kwaliteit en naleving van veiligheidsnormen zoals RoHS- en REACH-certificering. Zo bent u verzekerd van hoogwaardige stekkeradapters.

3. PCB-assemblage

Zodra de componenten zijn verzameld, worden eerst printplaten gemaakt met behulp van surface-mount-technologie (SMT) en vervolgens met behulp van Dual In-line Package-technologie (DIP). Dit geautomatiseerde proces garandeert een consistente kwaliteit voor massaproductie.

4. Huisvesting en Pin

Nadat het circuit is getest, is een geschikte behuizing nodig, gemaakt van gebakken kunststof, die de componenten beschermt tegen schade en omgevingsfactoren. Sommige klanten kiezen voor gangbare behuizingen, anderen openen de mal voor particuliere behuizingen, waardoor er een exclusieve adapter kan worden gemaakt. Kies voor de adapterpen altijd koper. Aanpasbare externe AC/DC-voedingen voor industrieel gebruik met hoogwaardige behuizingen voor duurzaamheid.

5. Kwaliteitscontrole en testen

Alle adapters worden vóór verzending onderworpen aan strenge tests, zoals controle op spannings- en stroomstabiliteit, beveiliging tegen oververhitting, bescherming tegen kortsluiting, EMI-afscherming, etc.

Hierdoor voldoen betrouwbare AC/DC-stekkeradapters met verwisselbare uiteinden aan de wereldwijde normen.

6Verpakking

Voordat we de adapter verpakken, moeten we altijd de tekens van de adapter afdrukken. Stroomadapters worden normaal gesproken verpakt in een gekleurde doos of blisterverpakking. Internationale reisadapters omvatten vaak uitwisselbaar stekker typees (Europa, Verenigd Koninkrijk, Australië, Noord-Amerika), die een grotere kleurendoos voor het pakket vragen.

7Branding en maatwerk

Wij bieden altijd op maat gemaakte stroomadapteroplossingen met klantlogo's, specifieke kleuren en aangepaste outputspecificaties. We hebben voor veel bekende merken gewerkt, die altijd om een uniek ontwerp vragen.

Laatste gedachten

Het productieproces van stroomadapters is een combinatie van nauwkeurige techniek, naleving van wereldwijde normen en gebruikersgerichte maatwerkoplossingen. Of het nu gaat om een universele reisstekkeradapter of een 100W GaN-oplader, aandacht voor detail garandeert veiligheid, prestaties en compatibiliteit.

Als u zelf een stroomoplossing bouwt of OEM-opties inkoopt, moet u het belang van certificeringen en milieuvriendelijke materialen niet onderschatten: belangrijke indicatoren voor energiezuinige voedingen die op de lange termijn betrouwbaar zijn.